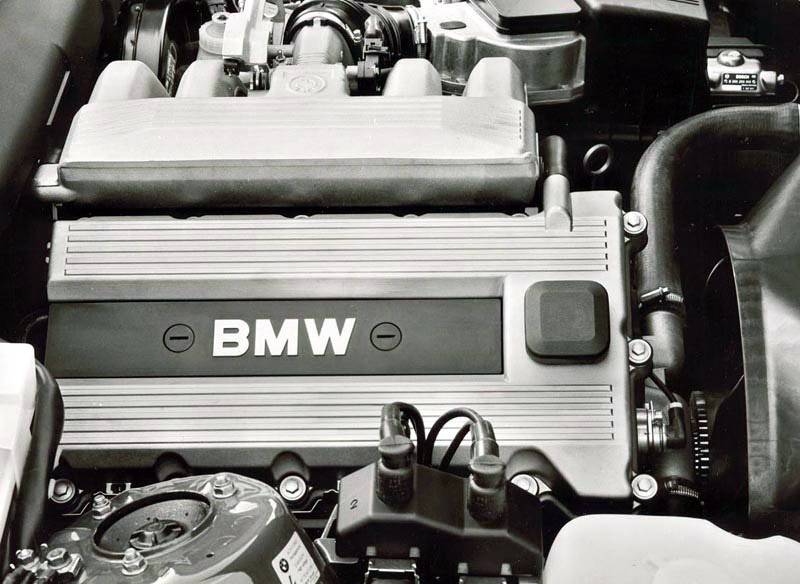

The BMW M42 engine is a mighty 4 cylinder that still has some advanced technology considering its age. The engine was first introduced in 1989 for the E30 318i models. One key characteristic we are focusing on is a feature of the exhaust valves.

Engine exhaust valves are some of the most highly stressed components on the entire engine. These valves can reach up up 800 degrees C (1,472 degrees F) in modern engines and actuate move over 70 times per second. Because of the tremendous amount of heat these valves see, they need to be properly cooled to prolong their life.

BMW's solution to properly cool the valves was to fill the hollow valve stems about 67% with sodium. At room temperature sodium is a solid, however at normal engine operating temperature the sodium turns to a liquid. In this liquid state the sodium has remarkable heat transfer properties. The movement of the valves up and down help transfer heat from the base of the valve to the tip of the stem. The top part of the cylinder head then extracts heat from the stem and dissipates it into the coolant flowing through the head as well as the oil circulating under the valve cover.

It is important to note that sodium filled valves are NOT to be disposed of without care. If the valves are melted down with sodium inside they are prone to exploding. Also, the valves are not to be used as tools in the shop for prying or as an impact mandrel exposing the pure sodium.

image source: mahle-aftermarket.com