What is the difference between direct and port injection?

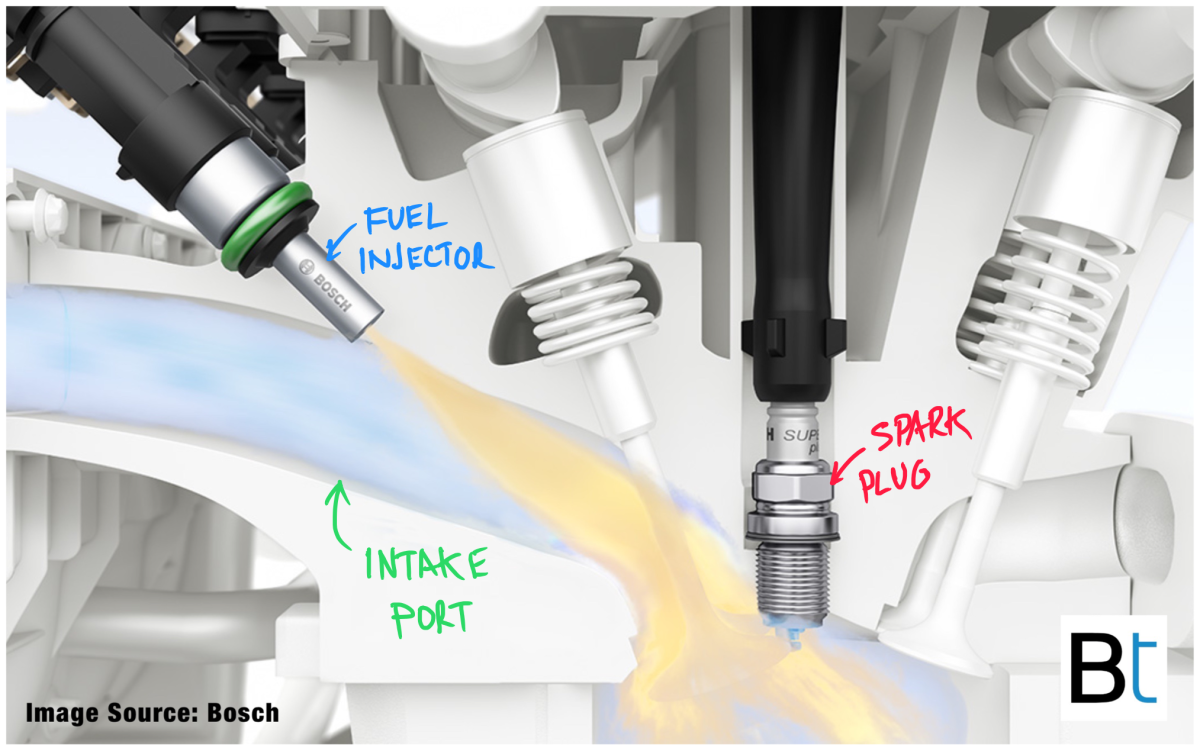

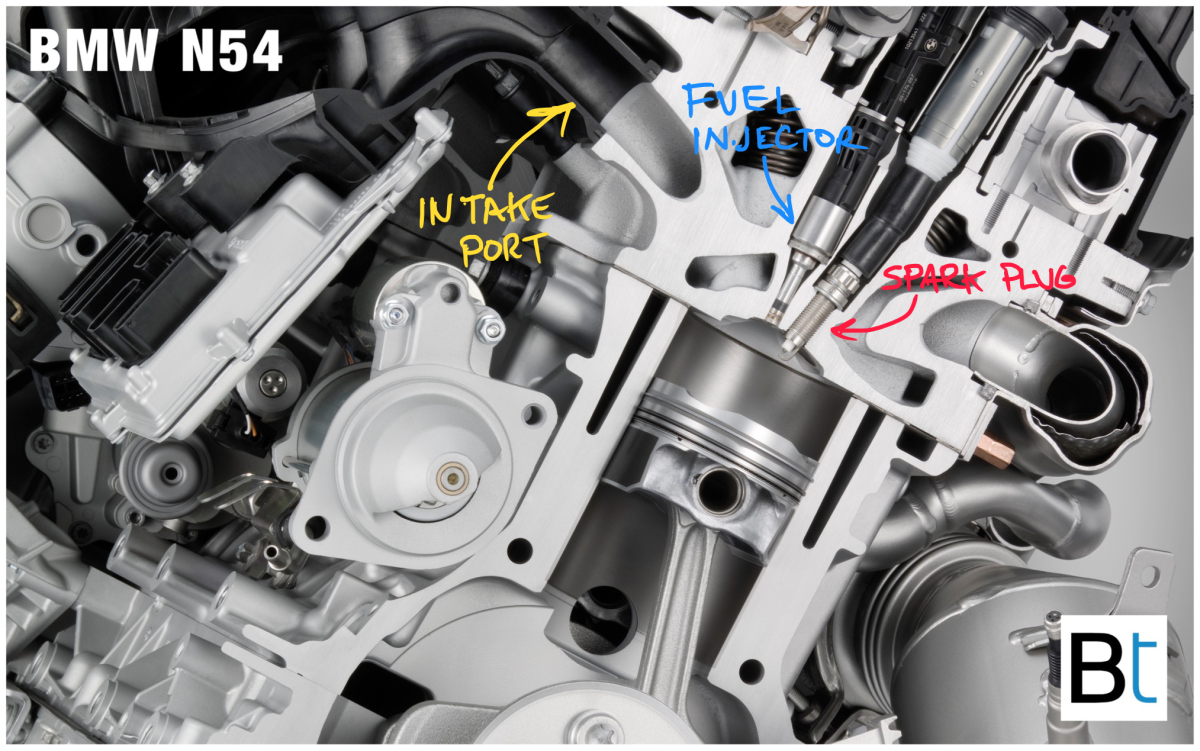

Direct injection sprays fuel directly into the cylinder head while port injection sprays the fuel into the intake ports. Reference the images below for further clarification on the location of the fuel injectors in the two setups.

BMW port injection

BMW direct injection

What are the advantages and disadvantages of direct injection?

By spraying the fuel directly into the cylinder head, the air-fuel mixture is more controlled and a cleaner burn results in better emissions. Compared to port injection, direct injection uses high-pressure fuel injectors which atomize the fuel into smaller particles, mist, creating a more efficient burn. Fuel economy is this improved by as much as 10 - 15%. Direct fuel injectors spray fuel over 1,500 PSI compared to port fuel injectors at around 50 PSI. Furthermore, by injecting the fuel directly into the cylinder head, the fuel helps reduce the cylinder head temperatures resulting it wasted energy in the form of heat.

The disadvantages of direct injection are that the injectors are much more expensive than traditional port injectors. Because the fuel flow is highly controlled the fuel flow rate is critical and must be calibrated to a higher degree of tolerance. Because of this high-pressure requirement, higher pressure fuel pumps are also required, thus, further increasing cost.

Due to the extreme heat produced in the cylinder head, the injectors are required to be manufactured from materials able to withstand this high heat and still function. As a result, the cost of each injector further increases when compared to port injectors.

Carbon buildup can occur on the intake valves. Due to the fuel being injected after the air passes over the valves, the fuel no longer acts as a cleaning agent to the valves. Direct injection engines will see carbon buildup on the valves as a result, decreasing fuel flow efficiency and performance. Further symptoms of carbon buildup on the valves may result in engine misfires and rough idle. This carbon buildup will require walnut blasting for removal, further increasing the cost of ownership over time.

Direct Injection Advantages

➊ Increased fuel efficiency

➋ Increased performance

➌ Decreased emissions

Direct Injection Disadvantages

➊ Higher cost of ownership over time

➋ Carbon buildup on the intake valves

➌ Potential for misfires, rough idle

What was the first BMW engine to use direct injection?

The first turbo engine to use direct injection was the N54 (2006 - 2016), the first naturally aspirated engine to use direct injection was the N53 (2006 - 2013, not sold in the USA). Since all modern BMW models are turbocharged, all current models feature direct injection.

Since the N53 was the first direct injection naturally aspirated motor, this makes the N52 the last port-injected motor BMW offered, 2004 - 2015.

How can I prevent buildup in my fuel lines and injectors?

Fuel system maintenance is often overlooked while maintaining a car. Replacing your fuel filters while keeping your fuel lines, fuel injectors and valves clean are a must. Maintaining a properly clean fuel system will ensure longevity of the fuel components as well as ensure performance.

There are a lot of options on the market for fuel system cleaners, however, we only suggest one product which trumps them all. Liqui Moly fuel system cleaner. 100% safe for direct or port injection fuel systems. Made In Germany.

This additive contains a highly effective combination of cleaning and treatment for all gasoline injection systems such as K, KE, L-Jetronic and similar systems. Removes deposits on injection valves, intake valves, spark plugs and in the combustion chamber and prevents them from reforming. Improves engine running and optimizes the exhaust gas values. Eliminates start problems and rough engine running. Maintains and protects the entire fuel system from wear, deposits and corrosion. Clean engines need less fuel and reduce emissions.

Where can I buy Liqui Moly Fuel System Cleaner?

BUY NOW by clicking HERE