BMW rod bearings have tarnished the legacy of the M brand due to premature failure. Learn about the details of how the failure occurs and how to prevent it.

What are engine rod bearings?

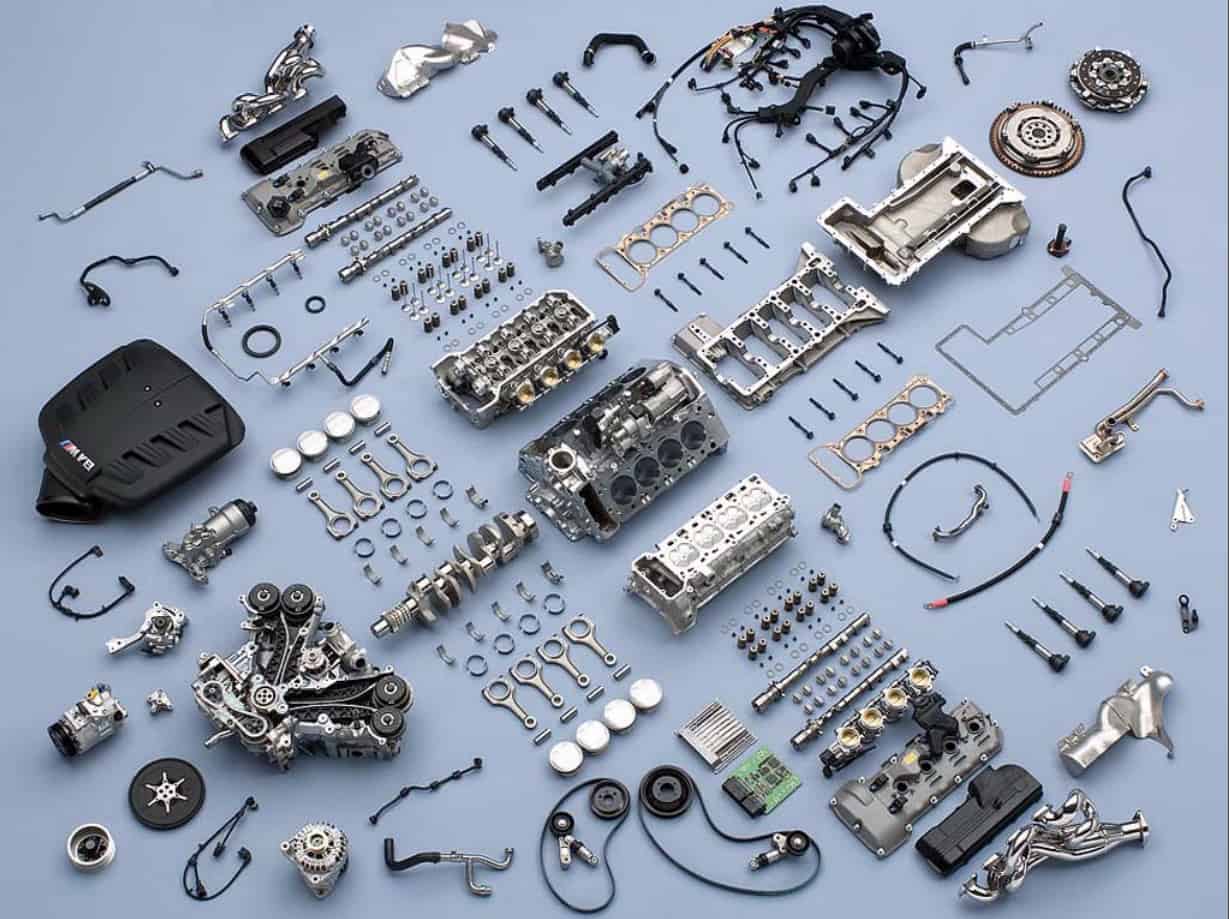

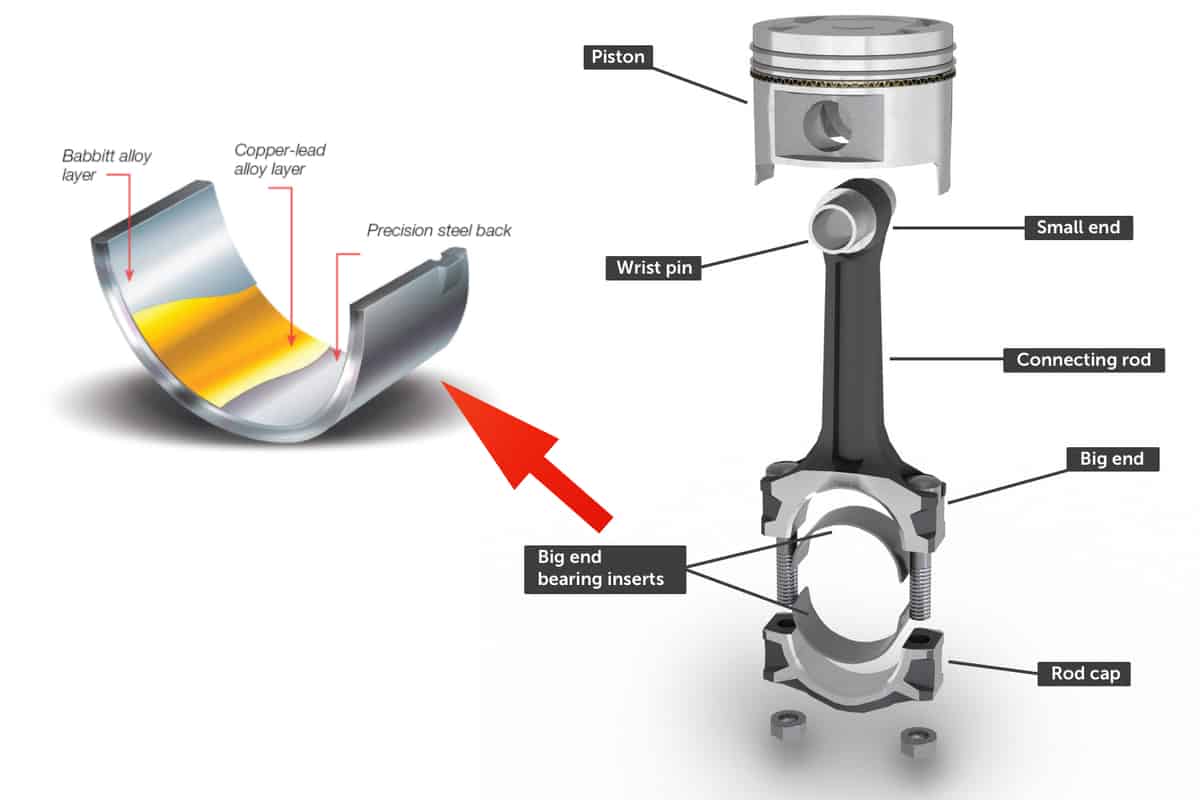

Connecting rods are what connects the piston to the crankshaft. The connecting rod moves the piston up and down as the crankshaft rotates. The connecting rod features inserts called rod bearings (more specifically “split sleeve bearings” which reduce the friction with the crankshaft.

Split sleeve bearings feature stacked layers of different metals which, when lubricated, provide a smooth surface for the connecting rod to rotate on about the camshaft. The split sleeve bearings do not feature ball bearings as one may assume. This is due to the extreme stresses and heat generated which would fail a traditional ball bearing setup. Insufficient lubrication will result in the two metals touching and ultimately lead to engine failure.

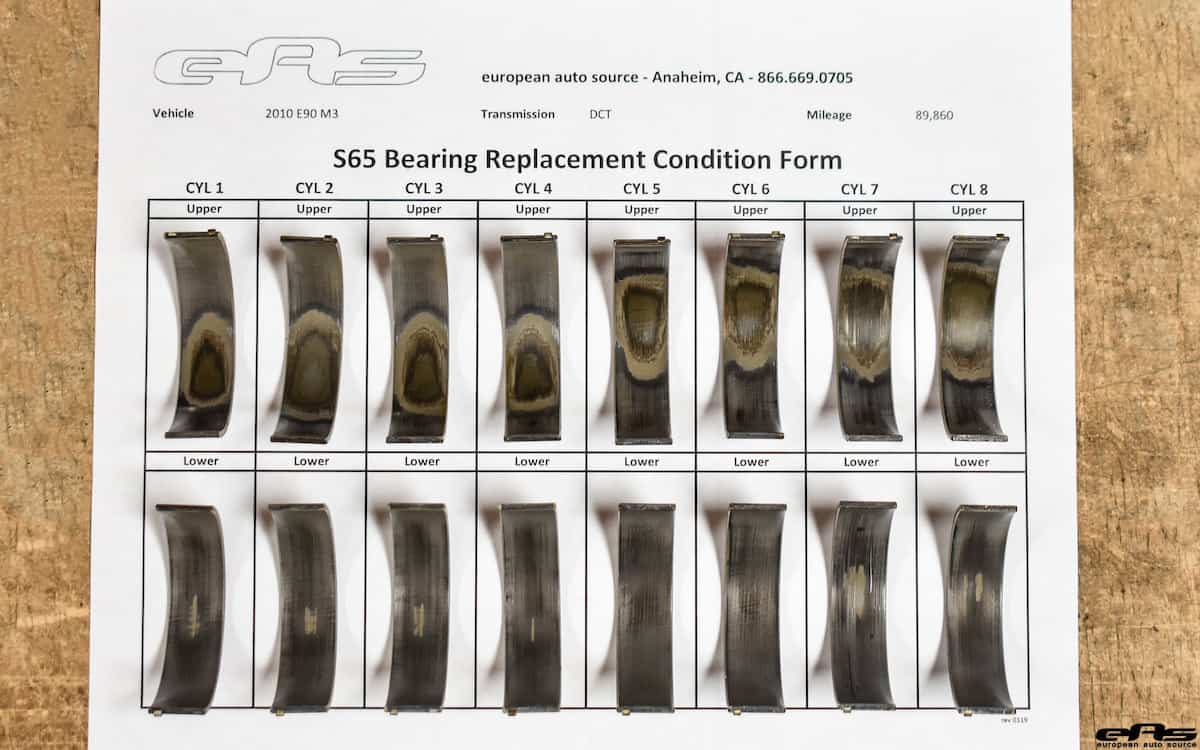

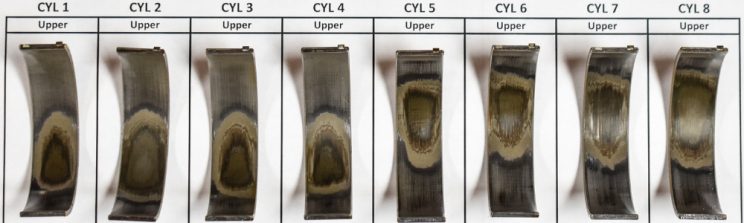

Reference the image below to see what worn rod bearings look like with insufficient oil supply.

piston, connecting rod, rod bearing

What BMW engines are most prone to rod bearing failure?

S54 (inline 6), S65 (V8), S85 (V10)

Why do BMW rod bearings fail?

The high revving nature of the S54, S65, and S85 engines require exceptionally tight tolerances between parts for the engine to perform optimally. The clearance gap between the crankshaft journals and connecting rod bearings is approximately .001 inches (.025mm). This gap makes it difficult for oil to travel between the two surfaces to provide sufficient lubrication, especially when the incorrect oil is used.

Factors that contribute to failure:

Using inferior oil. Phosphorus works together with Zinc to form a protective layer on surfaces when in extreme heat and pressure environments. This is ideal for rod bearings. The additives of Zinc and Phosphorus in oil is called ZDDP or Zinc Dialkyldithiophosphates which was common in older oils.

Upon original delivery, BMW used Castrol 10w-60 oil in its engines which featured the ZDDP additive, however, the oil has since been modified to meet the demands of newer emission standards. The downside of using phosphorus in oil is the carbon build-up which it produces. Carbon build-up will decrease the life of catalytic converters and oxygen sensors. Since the mid-1990s, the use of phosphorus in engine oil has been slowly phasing out to increase the life of catalytic converters.

Poor oil maintenance. Because the original maintenance schedule of these older cars assumed the use of ZDDP found in the oil, BMW recommended oil changes every 15,000 miles. Because modern oils do not feature the same levels of ZDDP, going 15,000 miles between changes can cause premature failure to the rod bearings.

Changing your oil at shorter intervals will ensure proper lubrication of the rod bearings between oil changes. For daily driven vehicles, it is recommended 10,000 miles between changes and 5,000 miles between changes for high RPM driving.

How often should rod bearings be replaced?

It is recommended to change the S54, S65, and S85 rod bearings every 60,000 - 80,000 miles. Replacing the rod bearings will allow for aftermarket bearings and connecting rod bolts to be fitted, providing more clearance than factory to sufficiently lubricate the parts. This work should be performed reputable shop as the work is highly specialized. Specific torque sequences are necessary to ensure the rod bearings deform properly to the crankshaft. Because oil properties are constantly changing, we recommend calling a local BMW performance shop to get the latest guidance on oil choice.

Where can I learn more information on oil weights and viscosity?

Learn more BIMMERtips information on oil by clicking HERE